The Specification Gap

No One Owns

Modern infrastructure demands ultra-pure coolants and stable flow characteristics. Yet cooling loops continue to rely on commodity seals from McMaster-Carr and Grainger—suppliers with zero cleanliness controls or verification protocols.

Mechanical Engineers

Specify material properties: EPDM, FKM, PTFE durometer and temperature ratings.

Coolant Chemists

Specify compatibility matrices and chemical formulations.

Cleanliness Specs

COMPLETELY UNCONTROLLED

"If it's not surface-verified, it's an uncontrolled variable in your thermal architecture."

Industry Research Confirms the Risk

"These cold plates have very small channels that can easily become clogged, placing the chip at risk of overheating and damage, thus requiring very stringent control of the coolant composition."

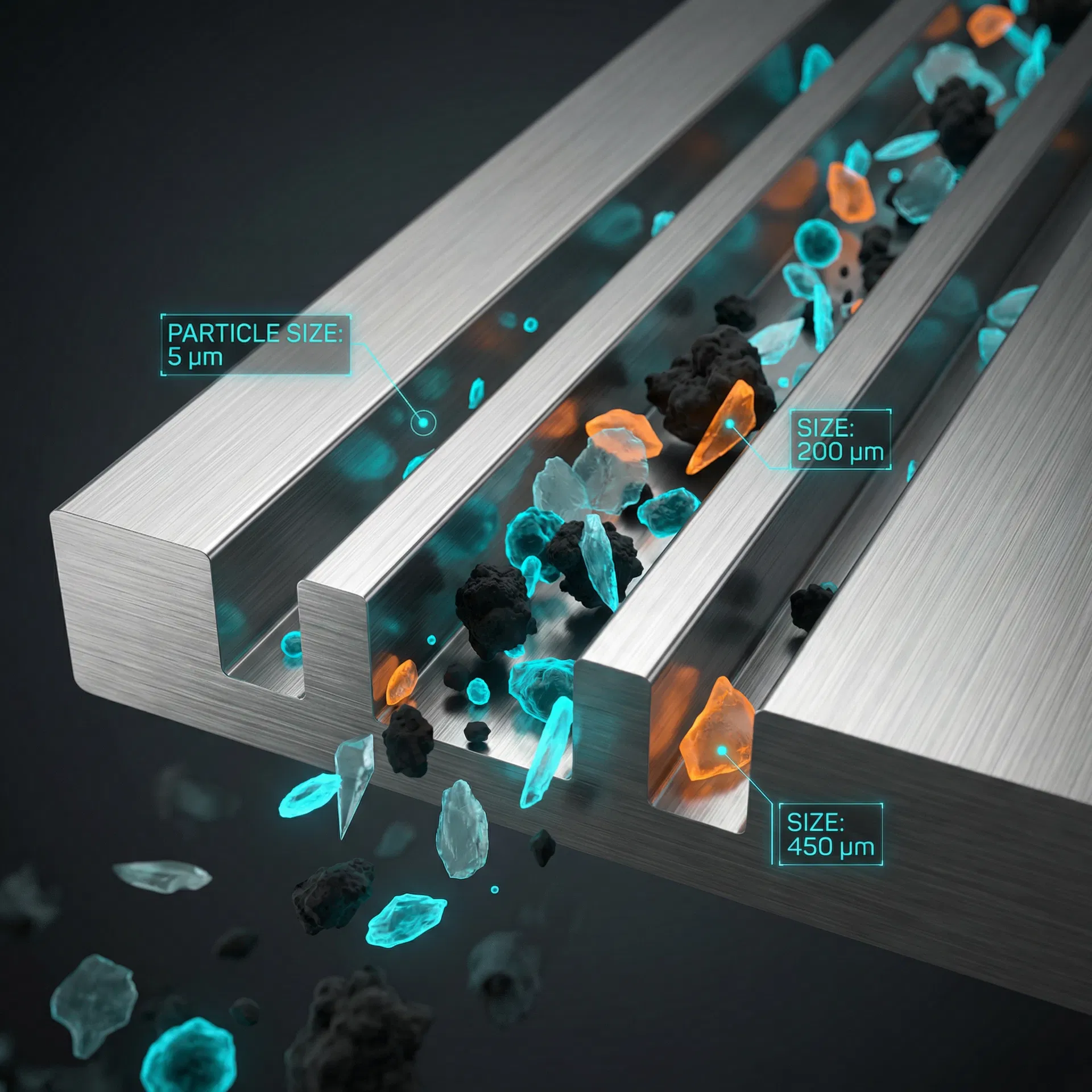

The Filtration Dilemma

In high-velocity microchannel cooling systems, filtration isn't free—it's a hydraulic tax that costs pressure, power, and margin.

The Engineering Tradeoff

To protect microchannels, you need ≤5-10 µm filtration. At D2C flow velocities (several m/s), that level of filtration causes unacceptable pressure loss.

Industry Reality

Most HPC systems avoid fine filtration entirely. Instead, they use coarse strainers (20-50 µm) and rely on component cleanliness upstream.

As filters load, ΔP rises → pump margin evaporates → flow instability

Fine filtration becomes operationally impractical at required velocities

VeriClean Seals™: Source Control, Not Downstream Mitigation

Uncontrolled seal-derived particulates force system designers to pay a continuous hydraulic tax: higher pump pressure, higher energy consumption, increased heat input into coolant, and reduced operating margin as filters load.

Microchannel Vulnerability

Direct-to-chip cold plates operate with extremely high fluid flow rates through microscopic channels. Suspended particulate contaminants inevitably produce fouling, scale formation, and blockage.

Particle Migration

Contaminants travel downstream from seal installation points directly to cold plates, lodging in microchannel restrictions.

Throttling & Derating

Increased delta-T across cold plates triggers automatic performance derating—reducing computational output.

Pump Mechanical Wear

Abrasive fines cause cavitation damage and impeller erosion, accelerating pump failure.

VeriClean Seals™: Reliability Insurance

Eliminate seals as a contamination risk factor through proactive surface cleanliness verification—not reactive troubleshooting after deployment.

95%+ Particle Reduction

ISO 14644-9 verified surface cleanliness with documented particle load reduction compared to commodity alternatives.

Cleanroom Processing

Semiconductor-grade ISO Class 5 cleanroom facilities with controlled environment protocols throughout the seal lifecycle.

Full Traceability

QR-coded certificates with laser particle imaging data, statistical process control, and 5-year archival records.

Reference Implementations: Lam Research • TSMC-class fabs • Tier-1 data center providers

Partnering with industry leaders: Parker • Kalrez • Vertiv • Iceotope

Chain of Custody Protocol

VeriClean Seals™ follow a rigorous chain of custody from cleanroom processing through final installation, ensuring contamination control at every step.

Receiving & Inspection

Document arrival in chain of custody record. Visual check for damage, temperature exposure, moisture.

Storage Protocols

Controlled environment (15-25°C, <50% humidity). Sealed until use. FIFO stock rotation.

Cleanroom Installation

Open only in ISO Class 7 or better cleanroom. Install immediately to minimize exposure.

Why Seals Matter More in 2026

The AI inflection point has triggered an unprecedented buildout surge. Liquid cooling adoption is projected to reach 30-40% by end of 2026, up from 19-22% today.

Rising Chip Density

Modern AI workloads operate at 700-1,500W per GPU, driving total rack densities to 80-120kW. This exponential leap creates thermal management challenges that air cooling simply cannot address.

Investment Concentration

New capital expenditure is flowing almost exclusively into High Density Compute (HDC) facilities. The AI inflection point and GPU roadmaps have triggered unprecedented buildout.

Technology Frontier

Liquid cooling is new territory for many teams. As thermal demands escalate, previously negligible risk factors—seals, coolant chemistry, assembly—suddenly become critical failure points.

Standards Evolution

Standards for coolant cleanliness (OCP, ASHRAE) are emerging, but seal cleanliness specifications remain largely unaddressed. This creates a dangerous gap.

Close the Contamination Gap

VeriClean Seals™ provide reliability insurance for liquid cooling deployments. Get data-driven confidence instead of commodity gambling.